Are you in search of a high-quality cross-cutting line with exceptional performance?

TENGDI Machinery delivers tailored cross-cut production line solutions catering to various needs, ranging from hot-rolled strips to the thinnest cold-rolled strips, encompassing materials such as aluminum and stainless steel. With strip widths spanning from 120mm to 2500mm, and strip thicknesses from 0.5mm to 20.0mm, our advanced and innovative technologies are finely tuned to meet the precise requirements of our clients.

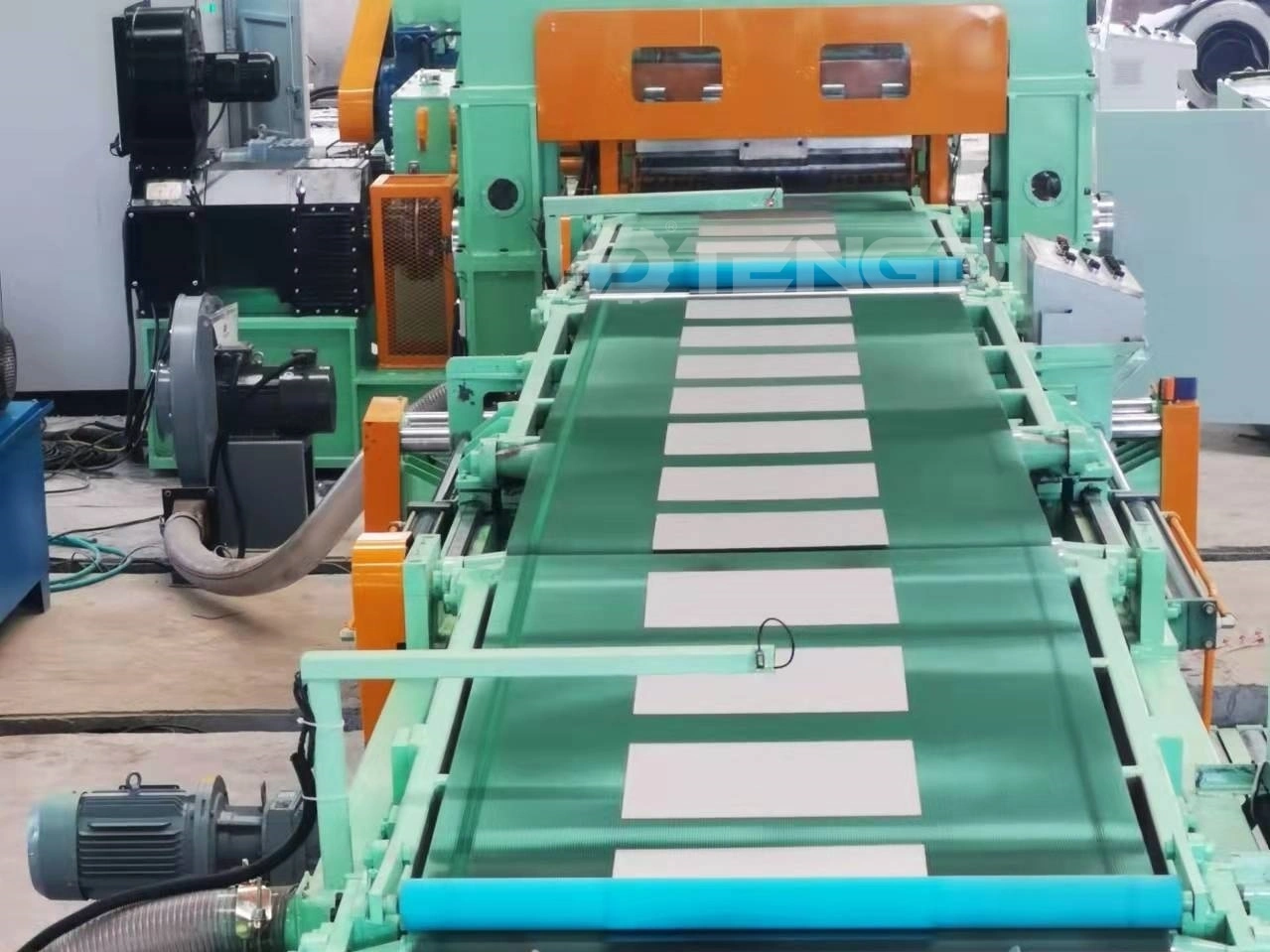

Standard Flow chart of cut to length machine:

Coil lifter --- hydraulic decoiler --- snubber roller --- pinch roll & pre-leveler --- loop bridge --- side guide roller --- main leveling machine --- encode & measuring device (with tail plate pinching) --- shear --- conveyor --- hydraulic lift platform --- stacker with blower device --- unload cart