Six-high Reversible Cold Rolling Mill

Model Number:

Six-high Reversible Cold Rolling Mill

Lead Time:

Est. Time(days) 60

Customization:

Comprehensive scheme customization of equipment

Service:

1 Year warranty

Are you looking for Six-high Reversible Cold Rolling Mill that will provide exceptional performance?

Tengdi Machinery is an excellent steel pipe making machine manufacturer with whom to explore collaborating. Tengdi provide a large selection of various Reversible Cold Rolling Mill choices that are intended to meet your unique requirements. We can be sure that you will get the finest Reversible Cold Rolling Mill option for your needs. Tengdi collaborate with skilled specialists who contribute their years of experience and guarantee that all of our works meet the highest standards.

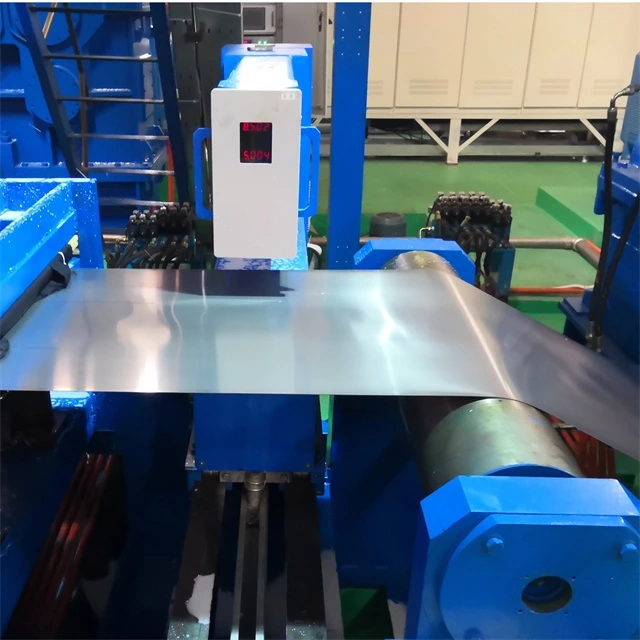

Six-high Reversible Cold Rolling Mill:

The factory currently adopts a single-stand reversible six-high HCM cold rolling mill. The working rolls of the rolling mill are equipped with positive and negative bending rolls, and the intermediate rolls are equipped with positive and negative bending rolls and moving. It is equipped with a pre-uncoiler and tension coils at the front and rear of the stand. Taking machine, thickness gauge, laser speed gauge, etc., can realize high-tension rolling and ensure high-speed and stable production of thinner specifications.

The pickled hot-rolled coil is rolled cold hard coil, which is composed of an uncoiler, a rolling mill and its front and rear coilers. And the rolling mill unit is equipped with hydraulic AGC, positive and negative roll bending and section cooling of work rolls, positive roll bending and moving of intermediate rolls, and front and rear double X-ray thickness gauges and double laser speed gauges

and other devices

Main equipment features of Six-high Reversible Cold Rolling Mill:

1. Single stand reversible six-high UCM cold rolling mill;

2. Work rolls are equipped with positive and negative bending rolls;

3. The middle roll is positively bent and moved;

4. Hydraulic pressing AGC control, the pressing cylinder is set at the lower part of the archway window;

5. The wedge mechanism adjusts the rolling line and is set on the top of the archway window

6. Tension coilers are installed before and after the rolling mill to achieve reversible rolling with high tension;

7. The working rolls are cooled in sections to control the shape of the plate, and the working rolls are automatically changed between types of kuns;

8. X-ray thickness gauges and laser speedometers are installed before and after the rolling mill:

9. The transmission system of the rolling mill, uncoiling and coiling millet adopts DC frequency conversion transmission.

10. The AGC adopts a high-speed controller to distribute the warehouse hydraulic servo system, which can realize high-precision fast response and cooperate with the laser speedometer to realize accurate AGC control of the amount in seconds.

Q: Are you manufacturer?

A: Yes. We are manufacturer. We have our own technical team. Welcome to visit us.

Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details!

Q: What info you need before you make the proposal?

A: The pipe diameter and thickness range which you need or the profile drawings material information, your special requirements and speed of the machine.

Q: How do you do QA?

A: We have special team do strict QA, this is our strengths:

(1)Every gear box will be tested for 8 hours with oil inside to guarantee there is no leak.

(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure it is in the range of tolerance critical parts will be inspected for all dimensions.

Products