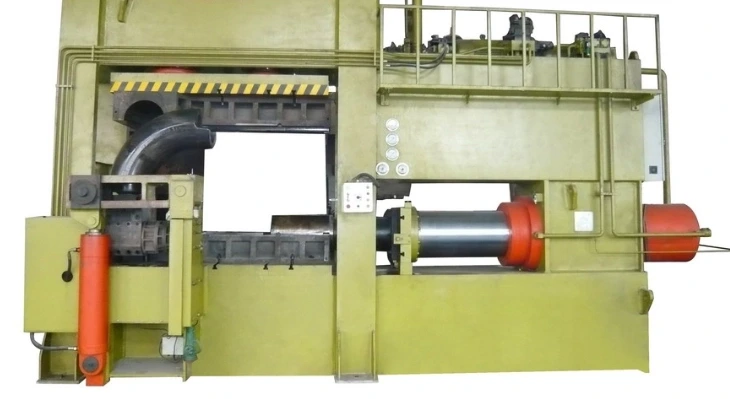

Erw Steel Hydraulic Mandrel Bending 1.5 D Elbow Forming Machine

Certification: CE

Model Number: GIL219

Payment & Shipping Terms:

Minimum Order Quantity: 1 set

Price: Negotiable

Packaging Details: Wooden box & Plastic wrapping

Delivery Time: 25 days

Payment Terms: L/C, D/A, D/P, T/T

Supply Ability: 10-15 sets/ month

| Product Name: | 1.5D Elbow Cold Makingm Machine | Material: | Stainless Steel Carbon Steel Alloy Steel |

|---|---|---|---|

| Packing:: | Wooden Box & Wooden Pallet | Warranty:: | 1 Year |

| Size: | Upto 89 | Color: | Green |

| Condition:: | New | Name: | Elbow Cold Forming Machine |

| Total Power: | 11Kw | LOCKING MAX TRAVELLING DISTANCE (mm): | 650 |

| PRODUCTION CAPACITY(mm): | 114-219 |

A234 WPB Automatic Seamless And Erw Steel Hydraulic Mandrel Bending Cold Forming Machine

1. Product Description:

stainless steel elbow machine have be made by our company which is divided into : machine main body, up cylinder , side cylinder , machine mold.When the Cold Forming Elbow Making Machine is working , the up cylinder will go down and lock the pipe and then the side cylinder will go forwards . When the side cylinder reach the cold forming elbow machine sensor and the elbow is formed the mould will bu up and then the elbow will be out of the machine .

For the mandrel type Cold Bending Elbow Machine , the speed is faster than the ball passing type but for the less thickness pipe fitting , it needs to go through by the ball pushing type and if theButt Welded Pipe Fitting is not good shape or not good dimension from Mandrel Elbow Making Machine we will use the ball to pass again for sizing the elbows.

Cold Forming Elbow Machine is different from Hot Forming Mandrel Elbow Machine . For the Cold Pushing Elbow Machine, the machine molds have two parts one is outside die which contain upper die and down die . Another part of the mold is inside mandrel or inside ball .

I. Work content of the supplier

1. Design and manufacturing.

2. Installation.

3, debugging.

Second, the performance

1. Used for cold push molding of stainless steel elbow.

2. Rated working pressure of oil is 25Mpa.The experimental pressure of the oil cylinder is 31.5MPa

3, main cylinder pressure 350T two, (cylinder inner diameter 300mm) effective stroke 900mm.

4. Side cylinder pressure is 200T, (cylinder inner diameter is 320mm) effective stroke is 800mm.

5. Elbow forming range diameter 133-219.

6, motor power 30KW.

7, 90° reversal mandrel demoulding

8, the environmental conditions of cold push machine: ambient temperature 5-38 degrees, relative humidity ≤82%, input voltage of three-phase four-wire 380V (-12%-- +15%), frequency of 50Hz±2%.The working time can be 24 hours a day continuous work, the air is free from corrosive media, the equipment must be operated in the workshop, there is enough space.

Products