Are you looking for high-quality ERW Tube Mill that will provide exceptional performance?

Our welded pipe machine has the characteristics of high-strength design, rigorous material selection, sufficient heat treatment, precision machining, fine assembly, stability and durability, high speed and high efficiency, energy saving and consumption reduction, and diversified welded pipe raw materials, so as to ensure the accuracy, quality and yield of welded pipe products.

According to the needs of customers, the company can carry out personalized design and customize welding pipe machines to meet customer needs and increase the added value of customer products.

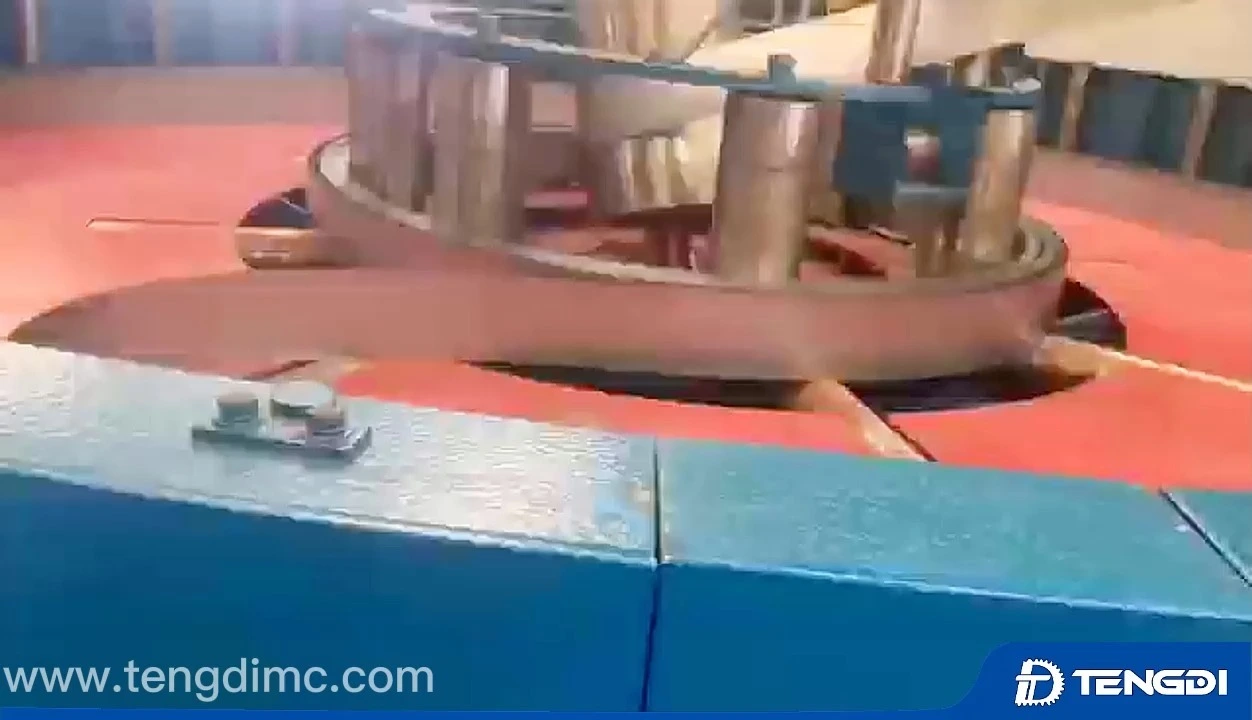

This set of HG127 welded pipe unit is currently installed in Venezuela. The whole line includes uncoiling, horizontal looper, forming and sizing host, cold saw, unloading rack and other equipment.

Q: Are you manufacturer?

A: Yes. We are manufacturer. We have our own technical team. Welcome to visit us.

Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details!

Q: What info you need before you make the proposal?

A: The pipe diameter and thickness range which you need or the profile drawings material information, your special requirements and speed of the machine.

Q: How do you do QA?

A: We have special team do strict QA, this is our strengths:

(1)Every gear box will be tested for 8 hours with oil inside to guarantee there is no leak.

(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure it is in the range of tolerance critical parts will be inspected for all dimensions.

Q: Why choose you? What is the difference between you and other Chinese supplier?

A: You can get higher quality product & better professional service from TENGDI with same price.

Q: What I should do if just start a new business?

A: Contact us immediately, we provide free consultant pre-sales service

Q: How about your service?

A:Our services include:

(1)Warranty is one year, Any parts damaged during warranty will be replaced for free!

(2)We provide spare parts for life time at cost price. Electrical parts such as boards and servo drives, we'll provide them for life time as well at cost price.

(3)We provide Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.