127 ERW Tube Mill details

The ERW 127 high-frequency straight seam welded pipe production line tube mill machine is designed to produce round pipes with diameters of 42mm-127mm , thicknesses of 0.9mm-6.0mm and square pipes of 30*30-100*100 tubes and 20*40-60*140 rectangular tubes.

| Type | HF Solid state steel pipe welding production line | Line speed | ≤100m/min |

| Round pipe dia | Φ42-Φ127 mm | Round pipe thickness | 0.9 - 6.0mm |

| Square tube size | 30*30-100*100mm | Square tube thickness | 0.9 - 6.0mm |

| Rectangular tube | 20*40-60*140mm | Rectangular tube thickness | 0.9 - 6.0mm |

| Pipe material | Carbon steel/Galvanized steel | Forming method | Round tube to square tube, quick change system |

127 Tube Mill Machine Features and Advantages

This case is a tube mill with a quick-change system that we exported to the South American market. It has been in production for more than a year and is in good production condition. It has received sincere letters of thanks from customers.

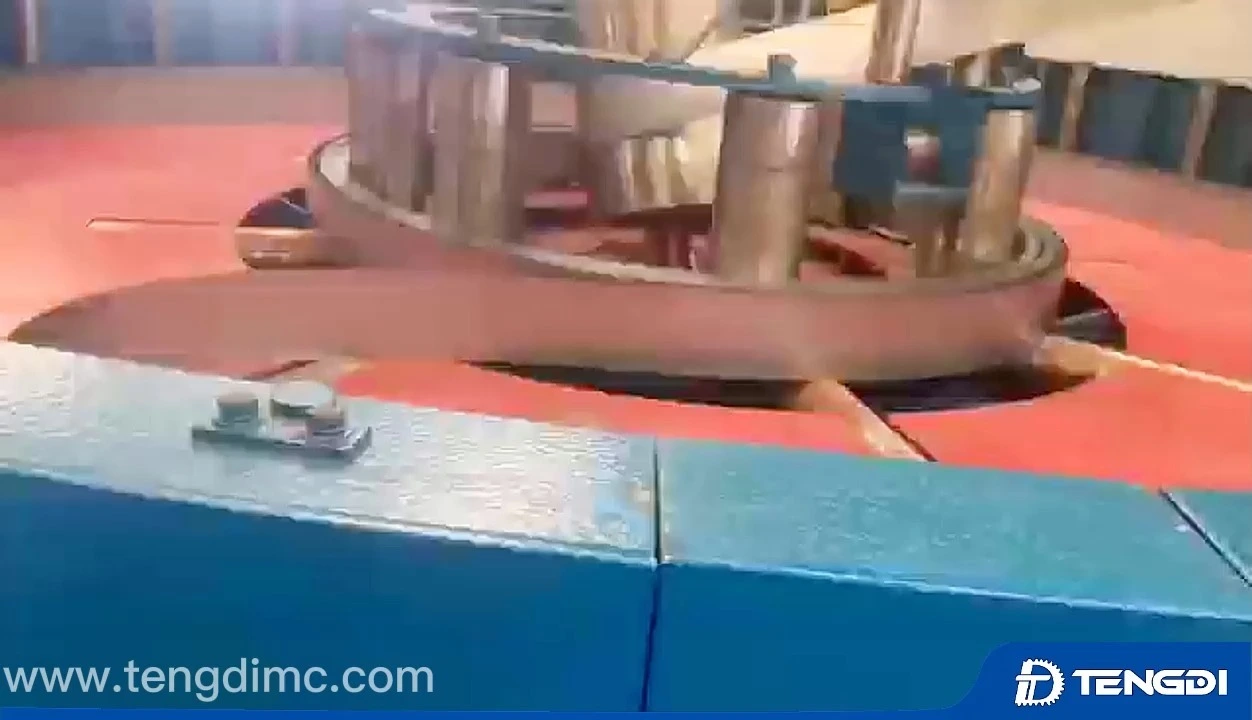

Tube mill machine rolls quick change system:

In response to customer demand, we adopted the shaft system quick change method in this case. The shaft system quick change refers to a spare set of roll shafts and rollers. When the customer wants to change the roll, the whole unit can be changed together, which greatly reduces the need for replacement. Rolling time improves the efficiency of the production line.

This system is designed for rapid replacement of shafting components, and can complete the replacement of bearings, shafts, bushings and other components in a short time, thereby reducing production line downtime and improving production efficiency.

Tube mill diagram

We have a professional technical engineer department to provide you with tube mill machine drawings suitable for your factory

Exhibition photos

certificate